Winkelwagen

Circular interior design

Do you have circular ambitions and would you like to translate these into your interior design? Gispen would be happy to share its expertise with you! We have clever solutions for reusing old furniture as well as for new and fully circular designed furniture. Suitable for office, educational and healthcare environments.

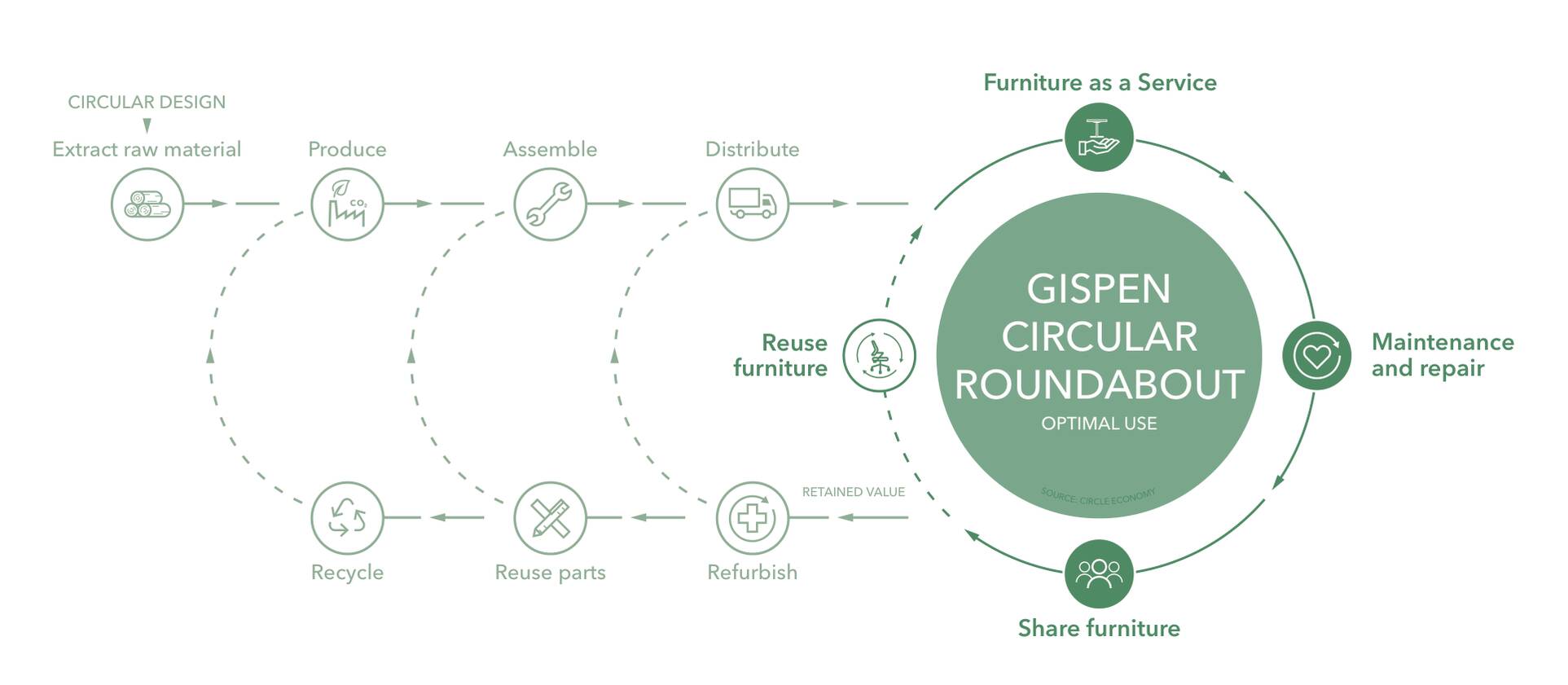

STAY ON THE GISPEN CIRCULAR ROUNDABOUT

Sustainable design guides how we design our collection and services. We create timeless design icons with an eye for the future. This way, Gispen furniture can be used 'as new' for generations. And it remains at the Gispen Circular Roundabout:

Gispen furniture has a circular design. Because the design is high-quality, timeless and easy to disassemble, we can easily repair or replace damaged parts. Want to know more about the Gispen Circular Roundabout?

NEW CIRCULAR FURNITURE

SUSTAINABLE MATERIALS

REFURBISHMENT

Does your current furniture no longer meet your expectations? Then we can refurbish it, or revitalize it. Think of reupholstering chairs, replacing damaged desktops or giving furniture another improvement. The furniture is then called REVIVED. We have brought all facilities, professionals and storage space together in the Circular Hub. This allows us to provide you with even faster and more targeted services in the circular field.

Circular successes

Our vision of circular entrepreneurship

Robbert de Jonge

Our customers often think they need new furniture in order to implement a new business concept correctly. Our product designer and I often manage to surprise clients when we present them with all the options for reusing their furniture. These are the days when I come home in a particularly good mood.

I am always searching for new ways to make optimal use of the resources that find their way back to Gispen. Closing the loops is our ultimate goal. Considering all the products we are refurbishing I think it's safe to say that Gispen is on the right track!

Related items

-

![Circulaire Hub Circulaire Hub landscapem]()

Revived

We refurbish both Gispen products and products from other manufacturers. When this process is finished, these products are given a REVIVED label.

-

![Universiteit Twente ITC Universiteit Twente ITC thumbnail]()

Circular quality scan

Clever implementation and reuse of current furniture within a new interior is a growing trend.

-

![Biosintrum Biosintrum landscapem]()

Circular product design

Would you like to reuse your current furniture but is it in need of an update or upgrade?

-

![Canon Production Printing Canon Production Printing landscapem]()

Vision & strategy

Learn more about our vision and strategy